Optimizing the order picking flow at Fabriek Logistiek

The essence

Fabriek Logistiek is a test centre where businesses can try and compare existing and new concepts regarding warehousing. As the logistics sector often works with job students and seasonal workers, they typically experience a high rotation in order picking employees which in term results in a suboptimal overall efficiency of the warehouse. Fabriek Logistiek was looking for innovative solutions to make order pickers faster deployable, and to decrease the error rate that comes with less experienced employees. We came up with a HoloLens solution that leverages a Digital Twin of the warehouse to guide / assist employees in real-time while picking orders.

The challenge

More efficient order picking

Many logistic companies work with job students and interim or seasonal workers in their warehouses. They often have a fixed-term contract of only a few months. Logically, this means a lot of time is spent repeatedly training new employees. This rotation in employees also causes a higher error rate. Therefore, Fabriek Logistiek wanted to investigate a way for more efficient guidance of newcomers, and a reduction in errors.

The Solution

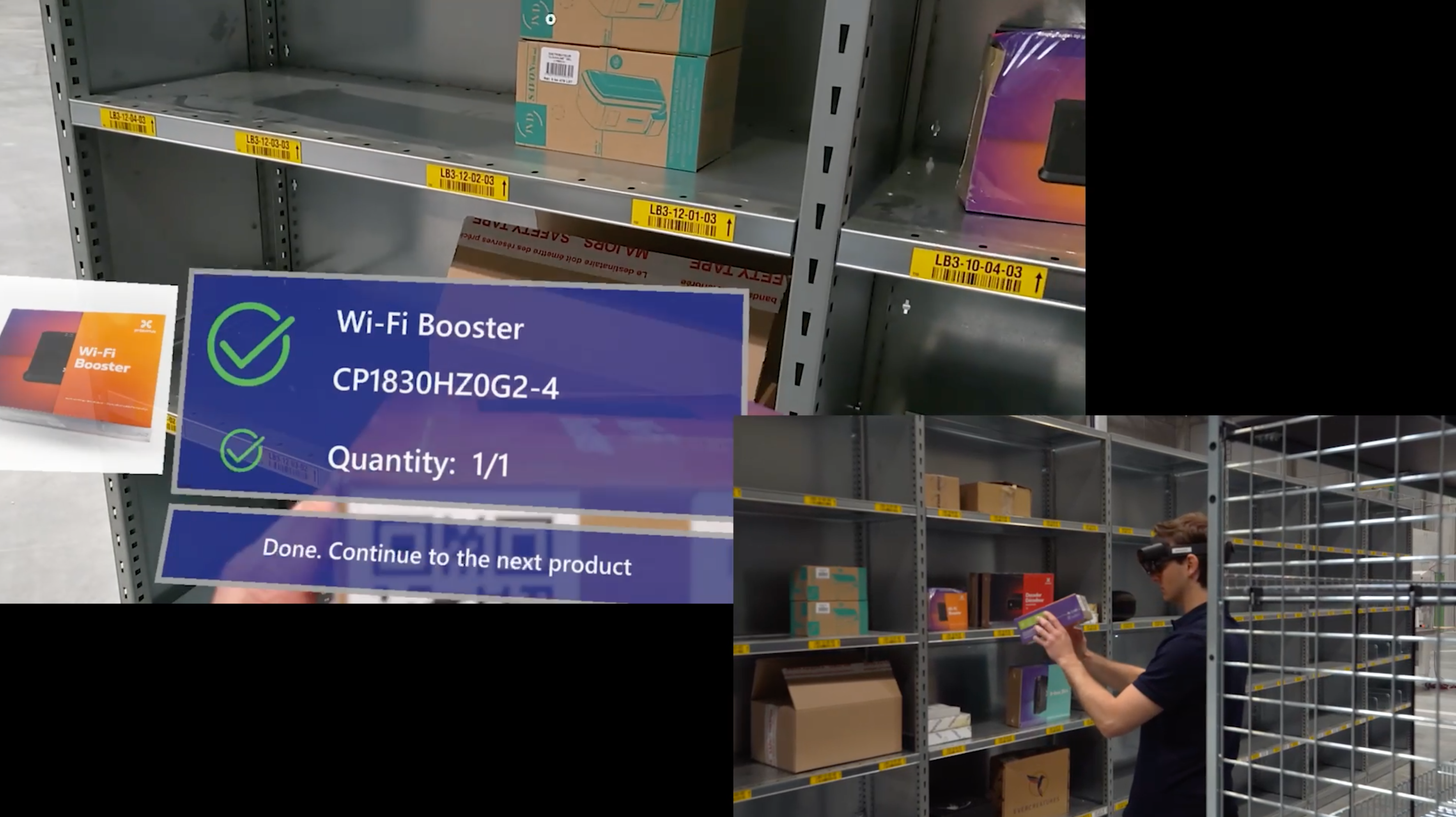

After a functional and technical analysis of the desired needs, we created a Digital Twin of their warehouse environment. As with our project for D’Ieteren, both physical layout(s) and operational flows were reflected. This allows our HoloLens application to guide new employees in real-time throughout their order picking process.

To start, the solution visualizes a list of items to be picked and shows holographic arrows to guide users to the correct products. We made this possible by connecting the Digital Twin to the warehouse’s WMS. That way, it can use the most current product information.

To minimize the risk of picking the wrong item, we added three ‘validation checks’ to the application. When arriving at the right aisle, the HoloLens will highlight the item to be picked. Next, it will scan a QR code on the product to make sure that this is indeed the item on the list. And lastly, a picture of the product is shown. Order pickers can then check for themselves if the image matches the item they’re about to pick.

On top of that, it’s important that the item has no damage whatsoever. Therefore, we added automatic damage detection to the app. By leveraging Computer Vision and AI, the solution checks whether there are abnormalities to the products packaging. Neat!