Twinning is winning, what are Digital Twins

Hi. We’re Mr. Watts

We combine your data with smart technology empowering better decision making.

We build Digital Twins.

But, what are Digital Twins?

In this blog we guide you through the theory, how you start with Digital Twins, and most importantly: what’s in it for you. To conclude, we show a number of good practices to take you through the full scope of the concept, right before we proudly add our own use cases as well.

The theory

What are Digital Twins?

To explain what Digital Twins are and how you can use them for better decision making, let's start with the theory. A Digital Twin is a virtual replica of an object, a process, an asset, etc.. Actually, anything in the real world. It can be anything from small objects (a robot arm for instance) to large ecosystems (the entire port of Antwerp), as well as even people.

A Digital Twin is controlled by real-time data so that it can behave like the real version of what it represents and respond as the actual entity should.

Afterwards you add machine learning, analysis, or any other technology to the Digital Twin to determine its behavior. This can also be done through a real 3D representation because geometric information can be essential data as well.

An example to clarify

Take Tesla, or any other self-driving car to put this theory into practice. On the large Tesla screen, you can see the Digital Twin of the car driving, based on real-time data (its camera, LIDAR sensors, etc.). The car and the environment surrounded are visible. Then simulations are run in order to tell the car how to drive.

This is a real-time simulation based on AI techniques. So you have a Digital Twin on your screen that immediately connects back to its real car. All calculations are fed back to its original object so it can drive on its own. For instance, if the Digital Twin needs to brake, the actual car follows its example and brakes to.

When we map the theory above to this example, you get a Digital Twin, fed by real-time data, which performs smart analysis and feeds back to the real version to trigger a certain behavior.

Application

When we look at the Tesla example, we see that the last step is ‘triggering behavior’. This isn’t always necessary. At Mr. Watts, we base our Digital Twin development on several steps or phases:

Collect: We collect real-time data using Internet of Things sensors, actuators, APIs, 3D images, etc. Actually, everything related to data input.

Connect: Afterwards, we use this data to build the Digital Twin.

Replicate: We build the Digital Twin based on a behavioral model, historical and real-time data, data orchestration and device management.

Empower: We add an analysis layer through AI or other forms of analysis to gain new insights about the Digital Twin. Sidenote, what’s the difference between AI and smart analysis? The latter can, for example, simply bring up the correlation between different data streams without necessarily learning from it. Take a warehouse situation, combining the positions of products and the movement paths of forklifts to find certain hot zones. This isn’t AI, but more traditional mathematical algorithms.

Decide: The final step is to make decisions based on the gained insights. This can be done manually or automated. If it’s automated, you can start over at step 1. This is why the last step is optional but still possible.

A concept

No technology, but a concept

To understand how Digital Twins work and how to implement them in your business, it’s important to know that a Digital Twin is an implementation concept, not technology in itself. It's about how you use data. Afterwards you can use different technologies to do something with the data.

For example, Apollo 13 is the very first example of a Digital Twin. Before the rocket was launched several simulators were created to predict, design, and draw out certain behavior. It was a very risky mission, during which these simulators were used to apply a lot of flexibility. Eventually the astronauts returned with an enormous amount of information about the launch.

NASA has used this concept a lot but never called it Digital Twins until 1995. The concept however dates back to 1970. Although it's 50 years old and definitely not new, it’s still innovative. Because with all the technology at hand now, we have more tools to extract value from Digital Twins.

Why use Digital Twins?

We showed you what a Digital Twin is and how we approach the setup of one. But why would you want to build one? What goals can you extract from using Digital Twins for your business?

Accurate and real-time simulations: base your decision making on data instead of feeling.

Deep and correlated insights: learn what processes cause trouble, what behavior doesn’t run smoothly or how to manage and organize your supply chain.

Data-driven decision-making: learn from predictions and precede eventual flaws or obstacles in your business processes.

Flexibility in decision-making in unforeseen circumstances: run different scenarios, allowing you to navigate smoothly instead of steering an oil tanker in a different direction when something goes wrong.

How to deploy?

Of course, we do not only build Digital Twins, we deploy them efficiently as well, helping your organization with better decision making. This is a process in three steps:

Connect: We identify and connect valuable enterprise and IoT data sources to the cloud. By combining historical and real time information we create a high quality data foundation.

Replicate: We build a Digital Twin that looks like and behaves identically to its real world counterpart. It replicates processes so you can assess and predict possible performance outcomes and issues.

Decide: We create tools that provide clarity to complex data. These allow for better decision making with large potential savings, improvements in maintenance and operational efficiency.

Use cases

Digital Twinning is winning

To show the enormous potential and power of Digital Twins, let’s guide you through a number of international use cases. We cherry picked a few good practices to show you the full scope of Digital Twins, so you get a clear view of its capabilities.

Port Of Antwerp (By Imec)

Imec built a Digital Twin of the entire Port of Antwerp. POA ships 85 million data messages per year. So yeah, data is crucial for the port. But how do we combine this data? Suppose we take a smarter approach to this. In that case, we can make predictive analyses based on weather conditions, for example, to increase the port's capacity. We have physical limitations, since the Port of Antwerp only has a certain size, so we need to be smarter to avoid obstructions. Apica, as the Digital Twins is called, helps with these processes to predict certain obstacles and help better decision making.

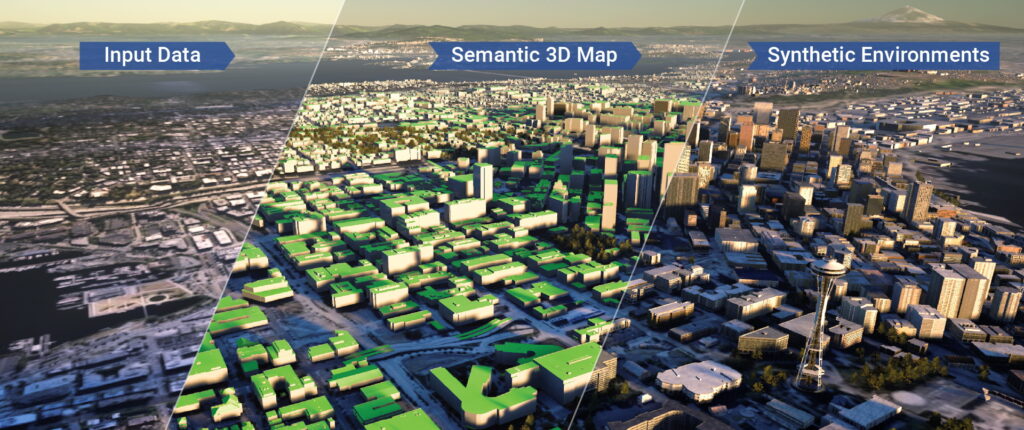

Blackshark.ai

Not exactly a use case, but more of a demonstration: how do you start building? Can you, for example, recreate an entire airport in AI? Blackshark creates the basis for Digital Twins of entire cities around the world. They don't just create a 3D representation, but a fully semantic model with all construction sites and other elements functionally labeled.

So how do they do it? They enrich satellite images with AI and create a 3D map from there. This can be used to create a Digital Twin. They have both the semantics and the visual representation. Google Maps is based on real photos, while this is synthetic and rendered by a computer. You can use a SDK (Software Development Kit) to create a Digital Twin of your environment without having to start from scratch. Very few people realize how much foundational data already exists, which they can directly link their data to and generate immediate value.

Duet

Another example of a Digital Twin project is Duet: a Digital Twin of the city of Ghent, which is part of a larger European project involving other cities. This Digital Twin includes data on air quality, noise levels, and other factors that can be used by policymakers to make real-time simulations and test the impact of their decisions. For example, if a bridge is closed, Duet can be used to predict the effects on traffic, air quality, and noise levels. This is a powerful tool for making informed decisions and gaining concrete insights into the impact of different choices.

Amazon

And we conclude with one of the most impressive uses of Digital Twins in the world: Amazon’s warehouse. Amazon has set up a Digital Twin for their warehouse, but they have even turned the entire concept of a warehouse upside down. Traditionally, we think of a warehouse with a fixed shelving infrastructure, but Amazon has implemented movable shelves, making it dynamic rather than static. These shelves are controlled by a Digital Twin that predicts market demand and optimizes the logistics flow based on the expected product demand.

Additionally, Amazon generates synthetic data to train their Digital Twins. Their robots are highly generic since they handle packages of all sizes using suction cups, and they are controlled by AI through computer vision. However, the boxes and packaging they handle change constantly, so Amazon trains their Digital Twins to recognize and handle new packages. The Digital Twin generates thousands of images to train AI models. This use case is an example of a Digital Twin that is so advanced that it controls reality.

So,

Watt are Digital Twins?

To conclude, we wrap up what Digital Twins are and how you can use them for your business. A Digital Twin is a virtual replica of a real-world object, system, process, organization, person, etc… Driven by real-time data (most of the time) which behaves and works exactly like its physical sibling, but is augmented with predictive analysis, Machine Learning or other AI techniques and finally frequently enhanced with an accurate 3D context and geometry.

As we’ve shown through international use cases, there’s a huge range in how a Digital Twin can be deployed in your business. And we wouldn’t be ourselves if we hadn’t applied it to our own customers. So in order to wrap up this blog about Digital Twins we urge you to read our own use cases. They give a great insight into how Digital Twins are put into practice in every day business as well, besides the Amazons and Teslas of the world.

BIM - Improved quality control at the construction site

Fabriek Logistiek - Optimizing the order picking flow at Fabriek Logistiek

D’Ieteren - Locating cars faster with Digital Twin and AR